By: Ben Boslaugh—Missouri State University, and CAPPA PD Committee

If you have a steam system – you have them. Understood by few, they are required for safe & efficient production and distribution of steam. Small or large they can make or break your system and are frequently taken for granted (or completely forgotten). Steam traps are installed in lines to drain condensate from a system without allowing the escape of steam (MM3 & 2 124). There are several types of traps, and the application (not the pipe size) should determine the type of trap installed.

At MSU we have several steam traps in our facilities and our utility distribution system. Over the years several folks had their hands in the maintenance and repair of these traps. A rule of thumb to remember from an energy perspective is that a trap that has failed in the “open” position will cost you at least $100 per year in energy (see Armstrong steam loss). As time passed, two issues became very apparent. Swing joints were being removed (resulting in threads failing as piping shifts), and test valves were being left out. These issues were compounded by new staff joining our team that had little steam experience.

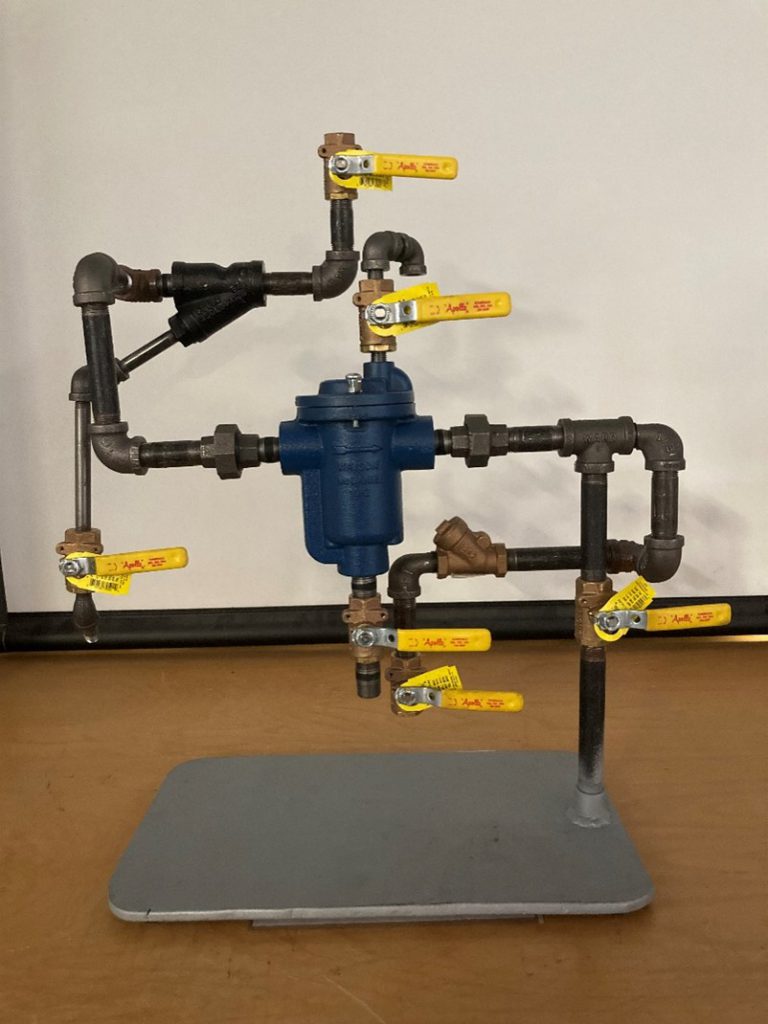

To remedy the situation one of our pipefitters built this training example. It resides in our main shop as a conversation piece and training aid.